Fiscal Period is the period

of time reflected in financial statements. Usually, the fiscal period is either

the calendar year or a quarter. Fiscal period is also known as an accounting

period.

The fiscal year is the consecutive

12-month period during which a business or organization plans its budget. It

does not have to be from January to December.

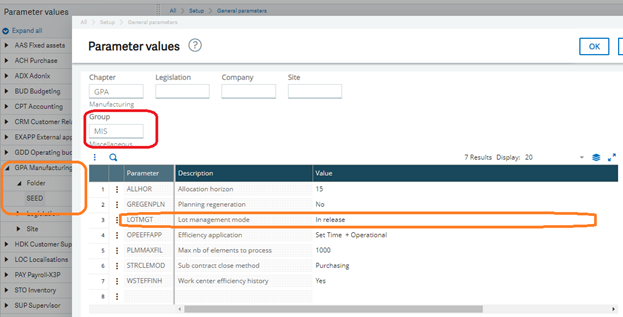

In Sage X3, sometimes we may find

difficulties like while running accounting task error comes for closing a

period. So, for solving these Sage X3 has a some in build functionality. Kindly

follow below steps for closing a period for particular month and for country.

Just follow the periodic tasks in the sequential order:

Step1:

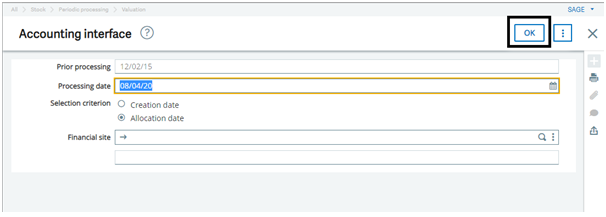

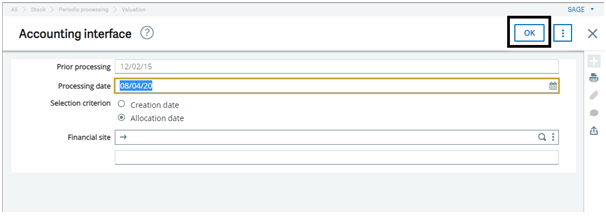

- Run

accounting interface before closing the fiscal period:

This is to check all the stock journals are posted properly and no error is

pending.

Navigate to : Stock -> Periodic Processing -> Valuation -> Accounting Interface

Refer above screen shot, just open the accounting

interface screen . Enter processing date and then click on OK button. This will

show, the journals are posted properly or not.

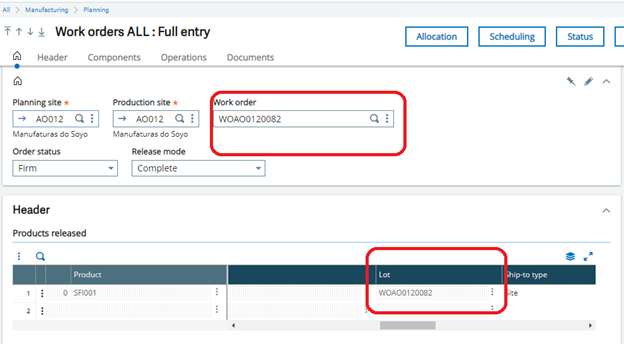

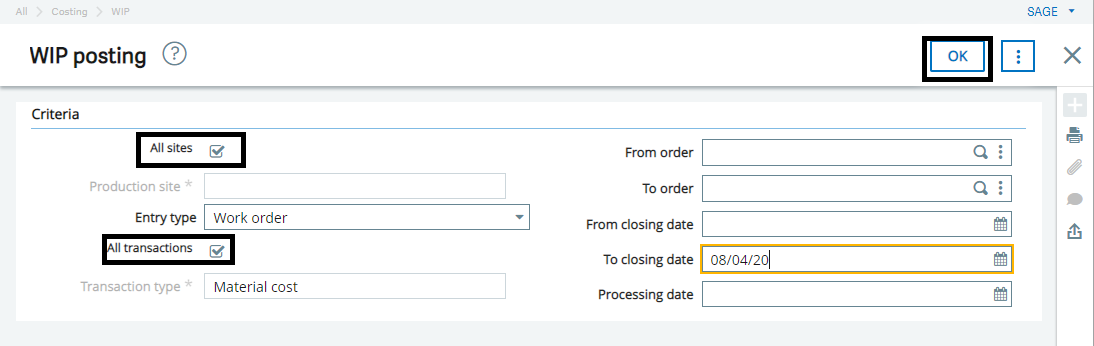

Step2: This step is important for only those companies which are manufacturing company. For non manufacturing companies we can skip this step:

Run WIP posting for all the Work

Orders which are closed: Make sure all the work order journals are posted

properly.

Navigate to: Costing -> WIP -> WIP Posting

Refer above screen shot, open the WIP

Posting screen.

Mark the ‘All Sites’ and ‘All

transactions ’checkbox as checked then click on OK button. This will show, all the

WO’s journals are posted properly or not.

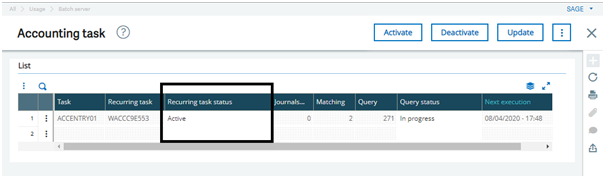

Step3:

To check accounting task, all the task

status should always be ‘Active’ and also check no journals are o hold status.

Navigate to: Usage -> Batch Server -> Accounting task

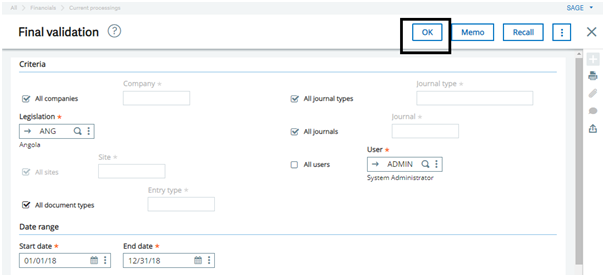

Step4:

Final Validation: This process is used

to finalize all accounting journals. Select all the mandatory fields and then

click on OK button in the Final Validation screen.

Navigate to: Financial -> Current Processings -> Final Validation

Step5:

Period Closing Process: For period

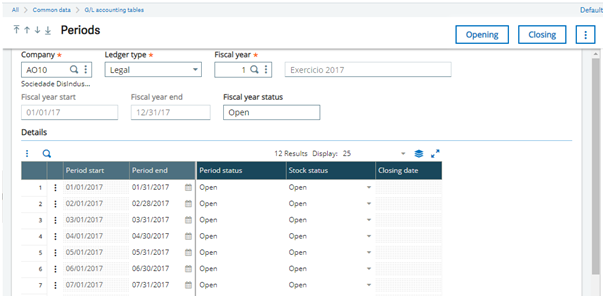

closing process, just open the fiscal period screen. Follow below path:

Navigate to : Common Data -> G/L accounting tables -> General -> Fiscal Period.

Now here as you can see the above

screen shot, all the stock status are open. Close them first from the drill

down.

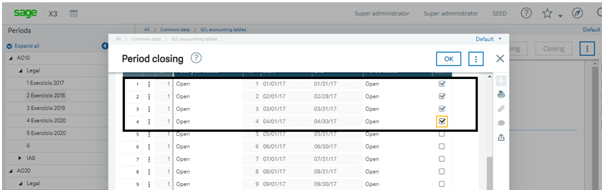

Now for closing accounting period,

follow below path.

Navigate to: Common Data ->

G/L accounting tables -> General -> Fiscal Period -> Closing button.

Now in this screen, select the period month for which we have to close the period status and then click on the OK button.

After clicking on the Okay button, the period status of all the selected period months gets closed.

Hence, after doing all the above steps we can close the fiscal period for particular month or year.

About Us

Greytrix – a globally recognized and one of the oldest Sage Gold Development Partner is a one-stop solution provider for Sage ERP and Sage CRM organizational needs. Being acknowledged and rewarded for multi-man years of experience, we bring complete end-to-end assistance for your technical consultations, product customizations, data migration, system integrations, third-party add-on development and implementation competence.

Greytrix caters to a wide range of Sage X3, a Sage Business Cloud Solution, offerings. Our unique GUMU integrations include Sage X3 for Sage CRM, Salesforce.com, Dynamics 365 CRM and Magento eCommerce along with Implementation and Technical Support worldwide for Sage X3. Currently we are Sage X3 Implementation Partner in East Africa, Middle East, Australia, Asia, US, UK. We also offer best-in-class Sage X3 customization and development services, integrated applications such as POS | WMS | Payment Gateway | Shipping System | Business Intelligence | eCommerce and have developed add-ons such as Catch – Weight and Letter of Credit and India Legislation for Sage X3 to Sage business partners, end users and Sage PSG worldwide.

integrations include Sage X3 for Sage CRM, Salesforce.com, Dynamics 365 CRM and Magento eCommerce along with Implementation and Technical Support worldwide for Sage X3. Currently we are Sage X3 Implementation Partner in East Africa, Middle East, Australia, Asia, US, UK. We also offer best-in-class Sage X3 customization and development services, integrated applications such as POS | WMS | Payment Gateway | Shipping System | Business Intelligence | eCommerce and have developed add-ons such as Catch – Weight and Letter of Credit and India Legislation for Sage X3 to Sage business partners, end users and Sage PSG worldwide.

Greytrix is a recognized Sage champion ISV Partner for GUMU Sage X3 – Sage CRM integration also listed on Sage Marketplace; GUMU

Sage X3 – Sage CRM integration also listed on Sage Marketplace; GUMU integration for Sage X3 – Salesforce is a 5-star rated app listed on Salesforce AppExchange and GUMU

integration for Sage X3 – Salesforce is a 5-star rated app listed on Salesforce AppExchange and GUMU integration for Dynamics 365 CRM – Sage ERP listed on Microsoft AppSource.

integration for Dynamics 365 CRM – Sage ERP listed on Microsoft AppSource.

For more information on Sage X3 Integration and Services, please contact us at x3@greytrix.com, We will like to hear from you.